How to Determine the Quality of Rotational Molds?

Rotational molding, also known as rotomolding, is a manufacturing process that involves creating hollow plastic products using a mold that rotates around two perpendicular axes. The quality of the rotational mold plays a critical role in the success of the manufacturing process. In this blog, we will discuss how to determine the quality of rotational molds.

- Material Selection

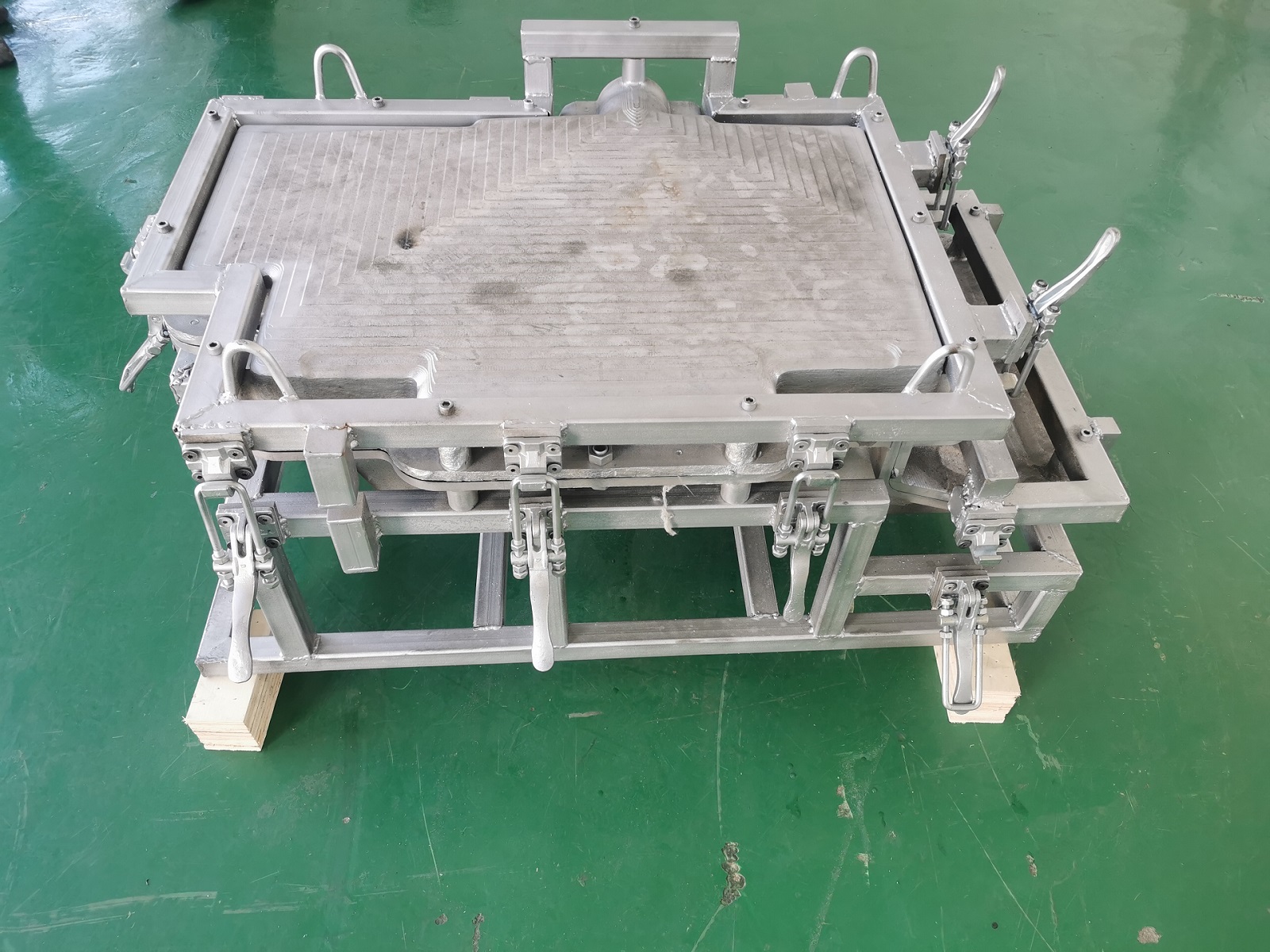

The quality of the material used to make rotational molds is critical to their durability and performance. High-quality materials, such as aluminum or stainless steel, are typically used to make rotational molds that are designed to last for years. The selection of the material must also consider the type of product being manufactured, the desired finish, and other factors such as temperature, pressure, and chemical resistance.

- Mold Design

The design of the rotational mold is a critical factor in determining its quality. The mold must be designed to meet the specific requirements of the product being manufactured. The design must take into account the material being used, the shape and size of the product, and any special features required. A well-designed mold will produce a consistent and high-quality product, while a poorly designed mold will result in defects, uneven wall thickness, or other problems.

- Manufacturing Process

The manufacturing process used to make the rotational mold is also critical in determining its quality. The mold must be made using high-precision machining techniques to ensure that it is accurate and consistent. The manufacturing process must also include proper heat treatment, polishing, and surface finishing to ensure that the mold is durable and corrosion-resistant.

- Testing

Once the rotational mold is complete, it must be thoroughly tested to ensure its quality. The mold must be checked for accuracy, consistency, and durability. Testing can include visual inspections, measurement of wall thickness, and pressure testing to ensure that the mold can withstand the stresses of the manufacturing process.

In conclusion, the quality of rotational molds is critical to the success of the manufacturing process. The quality of the material, mold design, manufacturing process, and testing all play important roles in determining the quality of the rotational mold. By paying attention to these factors, manufacturers can ensure that they produce high-quality products that meet the needs of their customers.

Leave a Reply

Want to join the discussion?Feel free to contribute!