Rotational Molding Surface Treatment

Rotational Molding Surface Treatment is the most import process to decide the final products surface effect.

Due to many customers ask our texture samples recently, so I write this article to show our factory surface treatment.

The texture can show the final roto molded products surface effect directly to the customers, then they can decide which types they need.

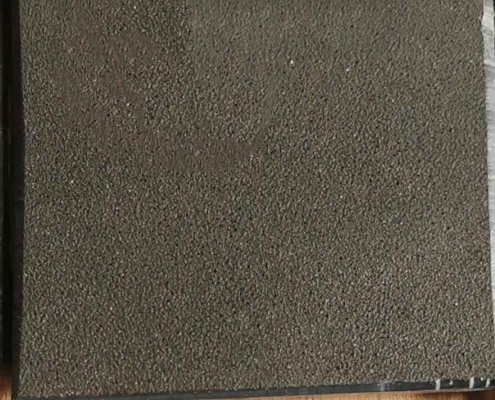

The are 5 photos show different texture based on different surface treatment:

1. Coarse Shotpeen

2. Fine Shotpeen

3. Polish

4. Hand Sand

5. Shotblast

Sometimes, the customers also will have extra Teflon Coating requirement, which will be talked at next article.

Fly Plastic main supply the above 5 surface treatment, and the most common is 1.5mm shotpeen on our side.

The shotpeen/sandblast/hand sand cost are same and our quotation will includ this cost, but if you need the polish surface treatment, the cost will be a little expensive based on the mould size.

Leave a Reply

Want to join the discussion?Feel free to contribute!