What is Roto Mold Process?

The roto mold process allows products to be manufactured in a way that creates extremely strong, long lasting, durable parts.

Rotomolded parts are resistant to deterioration from chemicals, the elements or environmental stresses.

The applications of this process range from playground equipment to nuclear warhead covers, from agricultural tanks to tornado shelters, from furniture to construction materials. The rotational molding process as well as the materials used during rotomolding pair to create these extraordinary parts.

Most processing of plastic requires force to be used to mold the plastic. Rotational molding utilizes movement of the mold to manufacture the part making the rotational molding process stress free.

Once a mold is filled with polyethylene powder it begins to rotate on two axis. It is moved through the oven where the rotating arm continues to move as the polyethylene powder is warmed and liquifies.

This liquid plastic is continually coating the mold building the walls of the part.

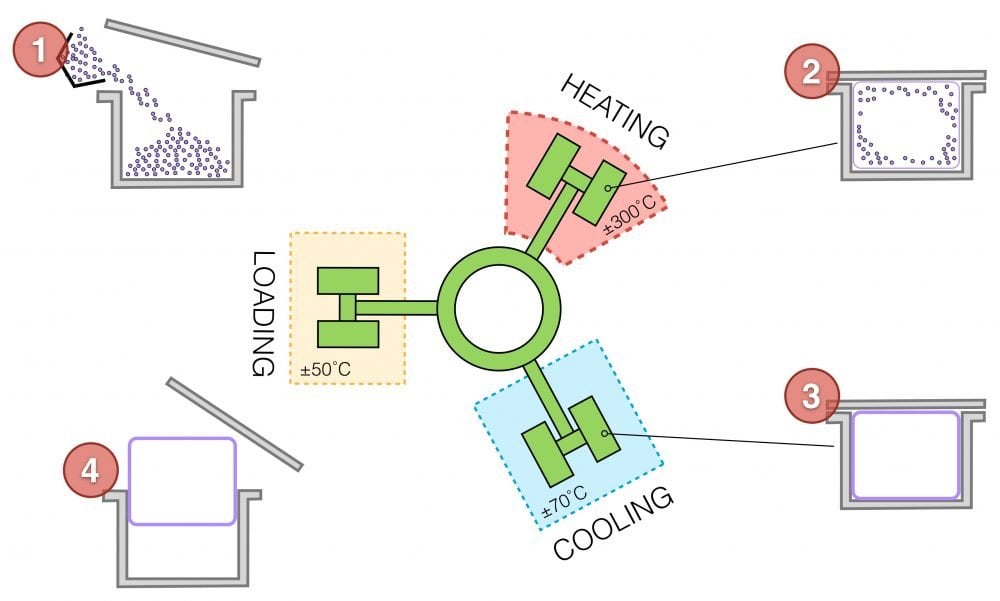

Summary:roto mold process includes four-stage

Stage One: Load powder polyethylene resin into the mold.

The first step is loading the resin in the mold. Pulverized material in a fine powder form is loaded into the prepared mold. The mold is then secured closed and rotated to ensure no powder is able to escape.

Stage Two: Mold moves into the heating chamber of the oven while rotating on two axes at a low speed.

Inside the oven the mould is bi-axially rotated (i.e., rotated around two axes) as the polymer melts and coats the inside of the mould.

The rotation speed is slow, less than 20 rotations/minute; the process is not centrifugal. During this phase of the rotational moulding process timing is critical. If the mould spends too much time inside the oven the polymer will degrade – this will reduce its impact strength.

If it spends too little time inside the oven melting of the polymer will be incomplete and it will not fully coalesce on the mould wall, creating large bubbles in the item.

Stage Three: Mold moves into the cooling chamber and is cooled by air or water spray or a combination of both, while still rotating.

After the melting has been consolidated to the desired level and the timing is right, the mould is removed from the oven and cooled. Cooling of the mould is typically done with air (by fan), water or sometimes a combination of both.

Cooling allows the polymer to solidify to the desired shape and shrink slightly so that it can then be handled by the operator and removed from the mould. The cooling time can typically be measured in tens of minutes.

It is important that the cooling rate be carefully measured because rapid cooling causes the polymer to shrink too fast and warps the part.

Stage Four: Mold is unloaded revealing the molded part.

When it has cooled sufficiently to be handled and the polymer can retain its shape, the mould is opened and the part is removed.

The moulding process can then be repeated by adding the polymer powder to the mould.

We welcome any customer to visit our factory to see the roto mold process anytime, you can contact us directly.

About this article, you can see more details from the origin link.

Leave a Reply

Want to join the discussion?Feel free to contribute!